What Are Laser Cut Screens?

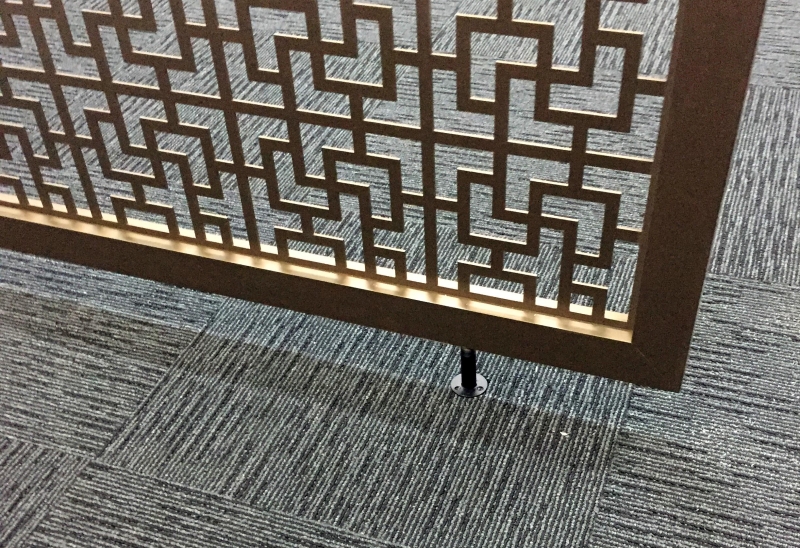

Laser cut products are manufactured using defined laser cutting tools. The laser is programmed to follow precisely the design that has been drawn on the computer. When cutting screens, the laser makes its cut through burning and melting the sheet of material. A gas such as oxygen is added, which eliminates the melted material, parting with a clean hole.

Typical materials that may be used to make a laser cut screen include steel, plywood aluminum and medium density fiberboard. With thicker materials, the cut edges are more likely to look to have lines running across them. These are formed when hot and cold areas meet.

When a laser cut screen is to be used to create a secluded space, by making it difficult to see what lies past the screen, what is called the pattern density becomes significant. Pattern density describes how easy or problematic it is to see through various laser cut designs. A loose pattern with big shapes and big holes may be less dense and appear more see-through than more complex, firmly packed designs that obscure the view. Pattern density might be a vital consideration for a laser cut screen used as a balcony panel or to obscure unsightly aspects of a garden.

The thickness of the laser cut materials used to make screens can vary, but there is typically a maximum width past which the laser will not cut. In the case of some materials like copper and aluminum, the maximum thickness is likely to be less than it is for others, such as wood and acrylics. Depending on the material, a number of laser cut screens can be colored. Wooden screens can be dyed, and metals such as aluminum and a number of steels can be coated with powder. Some metals, like non-stainless steel, will rust over time, and this may well itself be considered an ornamental effect.

HCDS has the best laser cut screens in town! Call us on +61 02 9648 2715 or fill in the contact form and we’ll be sure to help you.

Selecting a Product

Be clear about what you want to screen – is it just photographic or is it acoustic as well? Create a list of necessities your privacy screen must meet.

Entry spaces can truly benefit from the use of privacy screens. This is one area where they are becoming increasingly popular.

Decorative privacy screens can be utilized to divide large open plan spaces to generate ‘visual’ rooms. They can also be used to create an acoustic ceiling or wall lining in high noise areas.

There are numerous graphic styles and concepts you may choose from, so think about which style would optimally suit the interior look and feel of your own home. A screen is a sculptural bit which you can style in a really personal way; you may even desire to have a family picture laser-cut into the design.

Today’s material options and styles are numerous, and seeing contemporary architectural materials meeting with customary concepts is nothing short of remarkable.

There are some privacy screen materials that require some amount of care. In choosing the material of your privacy screens, make sure you think about how it is maintained to ensure that you will be able to properly maintain it in the future.

Compare the costs and quality of all these materials. Choose a privacy screen that is within your budget without compromising the quality.

HCDS is a growing company in the field of producing quality and cost effective aluminium screens. We endeavour to deliver the most cost effective way of moulding Aluminium Screens to help our customers outdo their competitors with an exhilarating play of shadow and light.

We specialise in manufacturing a broad range of steel and Aluminium fixed and adjustable louvres, security and shade solutions for homeowners, lattice and slatting products to provide state-of-the-art privacy, plantation shutters, home renovators, project builders, property developers, architects, commercial and industrial property owners along with councils.

With every piece of our steel and aluminium shade, privacy and screening produces custom-made and manufactured to your terms, we offer complete tractability not only in design, but also in selections of colours, styles and sizing.

Selecting a Design

Information You Need to Know

Ordering a Screen

Latest News

Well Framed Screens For A Range Of Applications

Displaying your brand identity can be as easy[...] Read More

The Designers Alternative To Traditional Privacy Screens

Are you in need of movable screens? These[...] Read More