All About Laser Cutting

A characteristic process laser has a beam of about a 1/5 of a millimeter in width, focusing 1000 to 2000 watts of energy. This is enough to melt most ordinary materials. Because lasers become less focused and lose energy as they pierce through a material, there is a limit of about 20 mm for the depth of the cut. Laser cutting machines are incorporated into a larger CAD/CAM (computer-aided-design, computer-aided-manufacturing) scheme that takes a design file and implements it on a work piece. These machines represent a stepping stone in the enduring trend away from hands-on manufacturing, putting human workforces in a more removed, artistic design role.

Because a laser is made up of photons, fragments of its energy can be reflected away by materials like aluminum and copper alloys. These materials are also thermal conductors, which means they distribute incoming heat more steadily throughout their volume. For this reason, carbon alloy and stainless steel are popular work piece materials for laser cutting. They are poor at absorbing heat, so heat is focused into the laser’s path more readily.

Typical laser cutters permit features as small as 1 mm in size. Specialized lasers frequently feature sizes that are even smaller, permitting the fabrication of true micro machinery. The first laser cuts were made in 1967, as part of a spinoff of a military research project engrossed on lasers. Because the beams used in cutting are “class 4” lasers, the machines are premeditated to ensure that human operators are never wide-open to them directly. All the cutting is done in the machine.

When making stuff, the minutiae can make all the difference in the world between looking unsoiled and polished and looking rushed. To get this right involves spending countless hours cutting accurate holes or edges. But as industrial technology gets ever more easily reached, the likelihoods for everyday folks get much better. One such tool is the laser cutter, a shortcut to splendidness that everyone should try out.

For your laser cutting needs, HC Design Solutions is the place to be! Come and talk to our team about your needs and budget. For inquiries, call us at +61 02 9648 2715 or visit our website at www.HCDS.com.au.

Selecting a Product

Be clear about what you want to screen – is it just photographic or is it acoustic as well? Create a list of necessities your privacy screen must meet.

Entry spaces can truly benefit from the use of privacy screens. This is one area where they are becoming increasingly popular.

Decorative privacy screens can be utilized to divide large open plan spaces to generate ‘visual’ rooms. They can also be used to create an acoustic ceiling or wall lining in high noise areas.

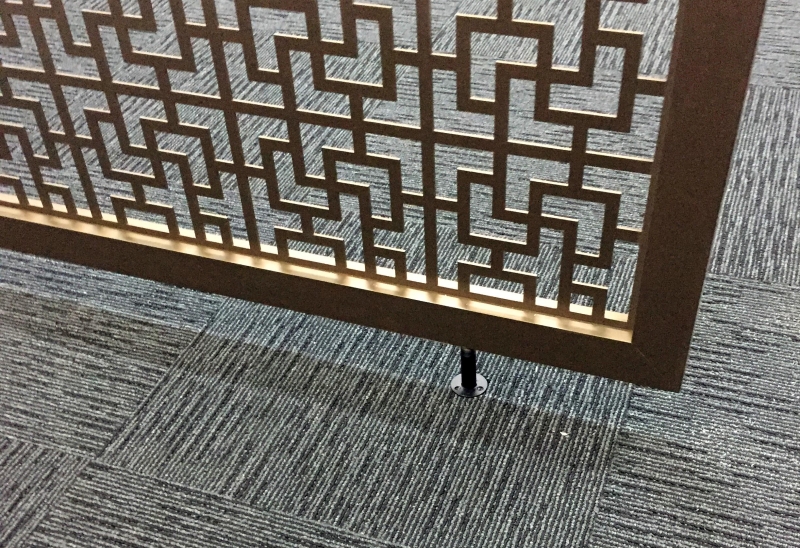

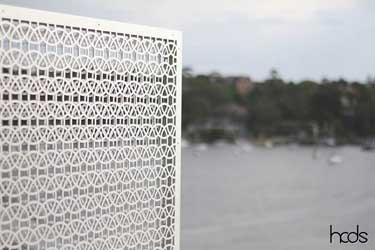

There are numerous graphic styles and concepts you may choose from, so think about which style would optimally suit the interior look and feel of your own home. A screen is a sculptural bit which you can style in a really personal way; you may even desire to have a family picture laser-cut into the design.

Today’s material options and styles are numerous, and seeing contemporary architectural materials meeting with customary concepts is nothing short of remarkable.

There are some privacy screen materials that require some amount of care. In choosing the material of your privacy screens, make sure you think about how it is maintained to ensure that you will be able to properly maintain it in the future.

Compare the costs and quality of all these materials. Choose a privacy screen that is within your budget without compromising the quality.

HCDS is a growing company in the field of producing quality and cost effective aluminium screens. We endeavour to deliver the most cost effective way of moulding Aluminium Screens to help our customers outdo their competitors with an exhilarating play of shadow and light.

We specialise in manufacturing a broad range of steel and Aluminium fixed and adjustable louvres, security and shade solutions for homeowners, lattice and slatting products to provide state-of-the-art privacy, plantation shutters, home renovators, project builders, property developers, architects, commercial and industrial property owners along with councils.

With every piece of our steel and aluminium shade, privacy and screening produces custom-made and manufactured to your terms, we offer complete tractability not only in design, but also in selections of colours, styles and sizing.

Selecting a Design

Information You Need to Know

Ordering a Screen

Latest News

Well Framed Screens For A Range Of Applications

Displaying your brand identity can be as easy[...] Read More

The Designers Alternative To Traditional Privacy Screens

Are you in need of movable screens? These[...] Read More